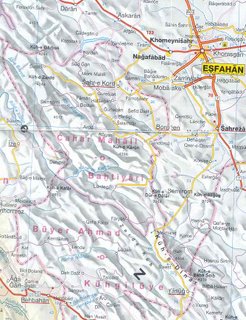

On my last buying trip to Iran I stayed with a Qashqai producer in Borujen, Godarz Hoshmand Emanlou, and went with him to visit some of the 100-odd weavers he has producing gabbeh carpets in the mountain villages in this area. He dyes all the wool himself, using vegetable dyes, which he then provides to the weavers. He also provides them with the designs to weave based on his knowledge of what the market wants. The weavers are paid for the product off the loom. Each week Godarz makes a trip to a dealer in the Tehran bazaar who buys the product and will finish the carpets for sale, i.e. shear the pile and wash the carpet. The weavers are all from Bakhtiari villages, though the gabbehs when they reach the markets in Esfahan, Shiraz or Tehran will probably be known as Qashqai gabbeh weavings.

On my last buying trip to Iran I stayed with a Qashqai producer in Borujen, Godarz Hoshmand Emanlou, and went with him to visit some of the 100-odd weavers he has producing gabbeh carpets in the mountain villages in this area. He dyes all the wool himself, using vegetable dyes, which he then provides to the weavers. He also provides them with the designs to weave based on his knowledge of what the market wants. The weavers are paid for the product off the loom. Each week Godarz makes a trip to a dealer in the Tehran bazaar who buys the product and will finish the carpets for sale, i.e. shear the pile and wash the carpet. The weavers are all from Bakhtiari villages, though the gabbehs when they reach the markets in Esfahan, Shiraz or Tehran will probably be known as Qashqai gabbeh weavings.In fact, there are many falsehoods in the carpet weaving business which makes it extremely difficult to know what you're buying as an end customer. One story retold to me when I passed through one particular village is that locally this village has an excellent reputation for its gabbeh carpets, yet Shirazi dealers fail to believe that this poor mountainous village could possibly deliver such excellent weaving, so they are sold as "Bushehr" gabbeh carpets -"Bushehr" having the reputation in the major carpet centres within Iran as having the best quality.

Here are some photos...

This is a very mountainous region, and visiting in January there was a lot of snow around. The villages are mostly unpaved, which meant wading through lots of mud. We even managed to get our vehicle stuck in the mud when we veered off the tar-sealed road.

This is a very mountainous region, and visiting in January there was a lot of snow around. The villages are mostly unpaved, which meant wading through lots of mud. We even managed to get our vehicle stuck in the mud when we veered off the tar-sealed road.

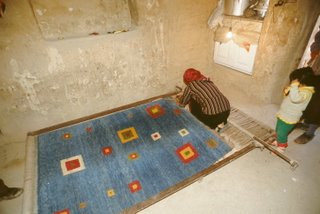

Mother and daughter weaving an undyed striped gabbeh carpet in Sarmour village. The carpet behind them represents 22 days work so far.

A 16 year old girl doing some of the weaving on a fine quality gabbeh carpet that is mostly the work of her older 24 year old sister.

A 16 year old girl doing some of the weaving on a fine quality gabbeh carpet that is mostly the work of her older 24 year old sister.

The same girl with her younger 8 year old sister weaving a plain red gabbeh runner size carpet. For these families, the bulk of their income comes from the girl's weaving in this subsistence farming area in the mountains. The reality is the better the weaving skills of the womenfolk, the greater the income they can expect. The older 24 year old sister who has been weaving for 12 years is in much demand by other gabbeh carpet dealers/producers.

This is one of the finished carpets being paid for. (The weaver was too shy to appear in front of the camera!)

A completed carpet being cut from the loom.

A carpet being measured - payment for the weaver is per square cm.

A carpet that was made on spec. by the weaver.

Naturally died wool drying in the sun. The madder root is used for the reds, indigo for the blue. Godarz does the dyeing of all the wool himself, with an assistant, using natural vegetable dyes.

1 comment:

looking forward to more fotos. Jud.

Post a Comment